Sublimation Printing: Unveiling the Art of Permanence and Vibrancy

Table of Contents

ToggleIn the dynamic world of printing technologies, sublimation printing stands as a testament to the marriage of science and art. It’s the technique that transforms a design from a digital canvas into a tangible masterpiece, maintaining its vividness and charm over time. This article delves deep into the realm of sublimation printing, unraveling its intricacies, applications, advantages, and innovations, while also exploring its environmental implications and future potential.

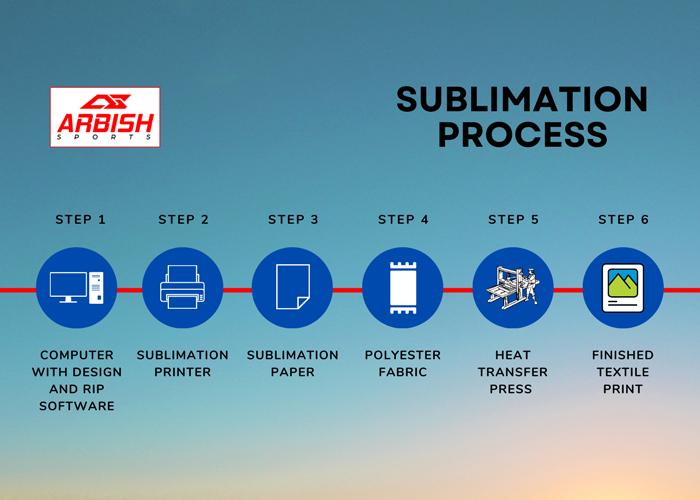

How Sublimation Printing Works: A Symphony of Heat and Color

Sublimation printing, at its core, is a process that takes advantage of the sublimation property of certain substances – the transition from solid to gas without passing through the liquid phase. Here’s how the magic unfolds:

1. Design Preparation

Begin with creating or selecting a design using graphic design software.

Remember, the final output depends on the quality and resolution of the original design.

2. Sublimation Inks and Transfer Paper

Specialized sublimation inks, often in CMYK color format, are used for printing.

Sublimation transfer paper is used to hold the ink temporarily during the transfer process.

3. Printing

The design is printed onto the sublimation transfer paper using a dedicated sublimation printer.

Precision and color accuracy are crucial at this stage to ensure the vibrancy of the final print.

4. Heat Transfer

The printed transfer paper is placed onto the target substrate (e.g., fabric, ceramic, etc.).

The substrate and paper sandwich are subjected to heat and pressure in a heat press machine.

5. Sublimation Process

As the heat increases, the sublimation inks on the paper transform into a gas.

The gas molecules infiltrate the substrate’s surface and embed themselves permanently.

Advantages of Sublimation Printing: Crafting Excellence

Sublimation printing offers an array of benefits that make it a preferred choice for numerous industries:

1. Unmatched Quality

Sublimation yields exceptional print quality with sharp details and vivid colors.

The colors are integrated into the substrate, resulting in a smooth and durable finish.

2. Durability and Longevity

Sublimation prints are resistant to fading, cracking, and peeling, ensuring longevity.

The embedded design withstands repeated washing, exposure to sunlight, and general wear.

3. Versatility of Materials

It’s not limited to just fabric; sublimation works on a range of materials including polyester, ceramics, metal, and more.

The process opens doors to creativity in various industries, from fashion to home décor.

4. Seamlessness

Due to the gaseous nature of sublimation, prints don’t have the textural feel often associated with traditional printing methods.

This seamless integration adds a professional touch to the end product.

Applications of Sublimation Printing: Where Imagination Meets Reality

The versatility of sublimation printing enables its applications across diverse sectors:

1. Fashion and Apparel

Customized sportswear, activewear, and fashion garments with intricate designs.

All-over prints that cover the entire garment, allowing for bold and expressive visuals.

2. Home and Interior Décor

Personalized cushions, curtains, tablecloths, and blankets for a touch of individuality.

Wall art, murals, and posters adorn living spaces with captivating visuals.

3. Promotional Merchandise

Corporate branding through custom printed mugs, keychains, phone cases, and more.

Branded textiles and accessories for marketing events and giveaways.

4. Sports and Recreation

Vibrant team uniforms and jerseys with unique designs.

Sublimated sports equipment like cycling jerseys, snowboards, and skateboards.

5. Personalized Gifts

Crafting meaningful gifts with a personal touch, such as photo albums, puzzles, and coasters.

Customized clothing and accessories for special occasions like birthdays and weddings.

The Sublimation Printing Process: Crafting Excellence Step by Step

Mastering the sublimation printing process requires meticulous attention to detail:

1. Designing the Masterpiece

Begin by creating or selecting a high-resolution design that aligns with the intended substrate.

2. Selecting the Right Substrate

Different substrates require different considerations for temperature and time during the heat press.

Choose a substrate compatible with the intended design and purpose.

3. Printing the Transfer Paper

Use a sublimation printer and compatible inks to print the design onto the sublimation transfer paper.

Ensure color accuracy and vibrancy during the printing process.

4. Heat Press Operation

Set the heat press machine according to the substrate’s requirements.

Time, temperature, and pressure must be precisely controlled for optimal results.

5. Sublimation Transfer

Position the printed transfer paper onto the substrate, ensuring alignment and smoothness.

The heat press machine activates the sublimation process, bonding the ink with the substrate.

Choosing the Right Equipment: Elevating Your Craft

The success of sublimation printing heavily relies on the quality of equipment chosen:

1. Sublimation Printer

Look for printers specifically designed for sublimation printing.

High resolution and color accuracy are essential for achieving the desired results.

2. Heat Press Machine

Invest in a heat press with adjustable temperature, pressure, and timer settings.

The machine’s size should accommodate the intended substrate dimensions.

3. Sublimation Inks and Transfer Paper

Select sublimation inks that match your printer’s specifications for optimal results.

High-quality transfer paper ensures proper ink absorption and release.

Tips for Successful Sublimation Printing: Crafting Perfection

Achieving exceptional sublimation prints requires attention to detail and a touch of finesse:

1. Color Calibration

Calibrate your monitor to ensure on-screen colors match the final printed output.

Color consistency is crucial for accurate results.

2. Test Runs

Always perform test runs on a small piece of the chosen substrate before full-scale production.

This helps to fine-tune settings and achieve desired results.

3. Alignment Precision

Ensure accurate alignment of the transfer paper onto the substrate.

Any misalignment can result in skewed designs and suboptimal results.

4. Heat Press Settings

Follow the manufacturer’s recommendations for temperature, time, and pressure.

Adjust settings based on substrate type and thickness for optimal ink transfer.

Recent Technological Developments: A Glimpse into the Future

Sublimation printing is not stagnant; it’s a field witnessing continuous innovation:

1. Advanced Sublimation Inks

The introduction of even more vibrant and colorfast sublimation inks.

Enhanced color gamut and improved resistance to fading.

2. Precision Heat Presses

Heat press machines with integrated technology for precise temperature and pressure control.

Enhanced automation features for consistent and reliable results.

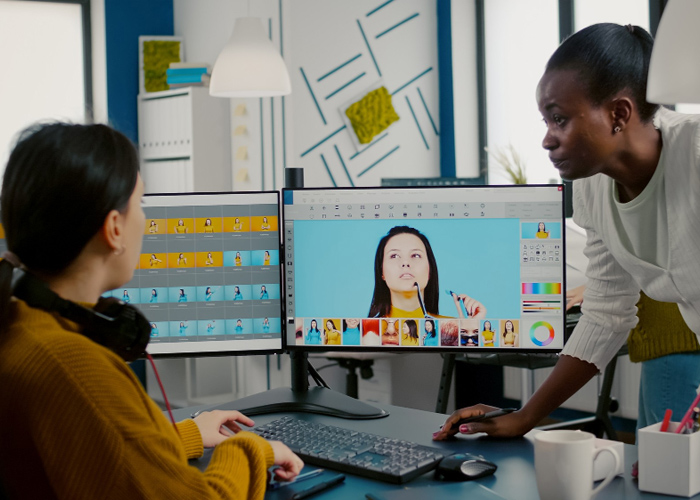

3. AI and Design Integration

Integration of AI-powered tools for design creation and enhancement.

Automation of repetitive tasks, reducing manual workload.

Environmental Considerations: Towards Sustainable Printing

Sublimation printing isn’t just about quality; it also has environmental implications:

1. Reduced Waste

Sublimation printing produces minimal waste as it doesn’t involve excess ink.

The entire ink quantity is utilized in the printing process.

2. Eco-Friendly Inks

Eco-friendly sublimation inks that are water-based and have reduced environmental impact.

These inks adhere to strict environmental standards.

3. Sustainable Substrates

Exploration of sustainable substrates, such as organic textiles and biodegradable materials.

A shift towards environmentally conscious choices in printing materials.

Future Trends in Sublimation Printing: Pioneering the Uncharted

The journey of sublimation printing is far from over; future trends hint at remarkable possibilities:

1. Integration with 3D Printing

Combining sublimation with 3D printing for customized shapes and textures.

The fusion of design and function in entirely new ways.

2. Fashion and Interior Domination

Penetration into the high-fashion world with personalized and artistic designs.

Interior designers utilize sublimation for intricate wall coverings and unique furnishings.

3. AI-Generated Designs

AI-generated designs that cater to individual preferences and current trends.

A new era of personalized, one-of-a-kind creations.

Conclusion:

Sublimation printing isn’t just a technical process; it’s an art form that allows ideas to materialize into vibrant realities. Technology’s blend of permanence, versatility, and environmental consciousness makes it a staple in various industries. As innovation continues to push the boundaries, sublimation printing stands are poised to deliver new dimensions of expression and creativity.